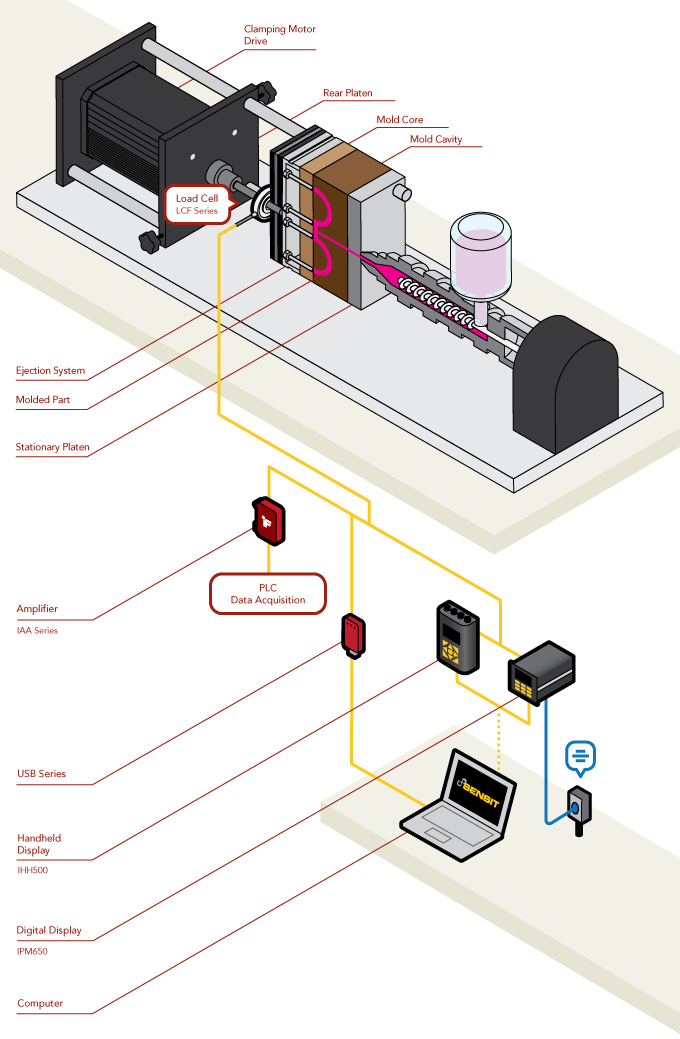

Plastic Injection Molding Force Feedback

.

During plastic injection molding and die casting, the mold is clamped to resist the rapid thermal expansion and contraction caused by the molten material filling the mold cavity. Defective parts can be created if the mold is not held tightly enough to withstand the thermal load throughout the molding and casting process. To mitigate these thermal effects, "wafer" type load cells are placed at the flange contact points, allowing machine monitoring processes to adjust clamping forces.

.

How it works :

- LCF Pancake Load Cells are fitted in-line of hydraulic pressure or screw-type clamps measuring the compressive force applied to the mold.

- As the mold expands and contracts due to the molten material, the load cell provides feedback to the PLC with the new compressive force.

- The feedback is used to adjust the clamps in real-time to maintain mold compression.

- When paired with the IAA Series Analog Amplifier, the load cell can provide a variety of amplified outputs such as 0-10 V or 4-20 mA signals for the PLC.

.

.