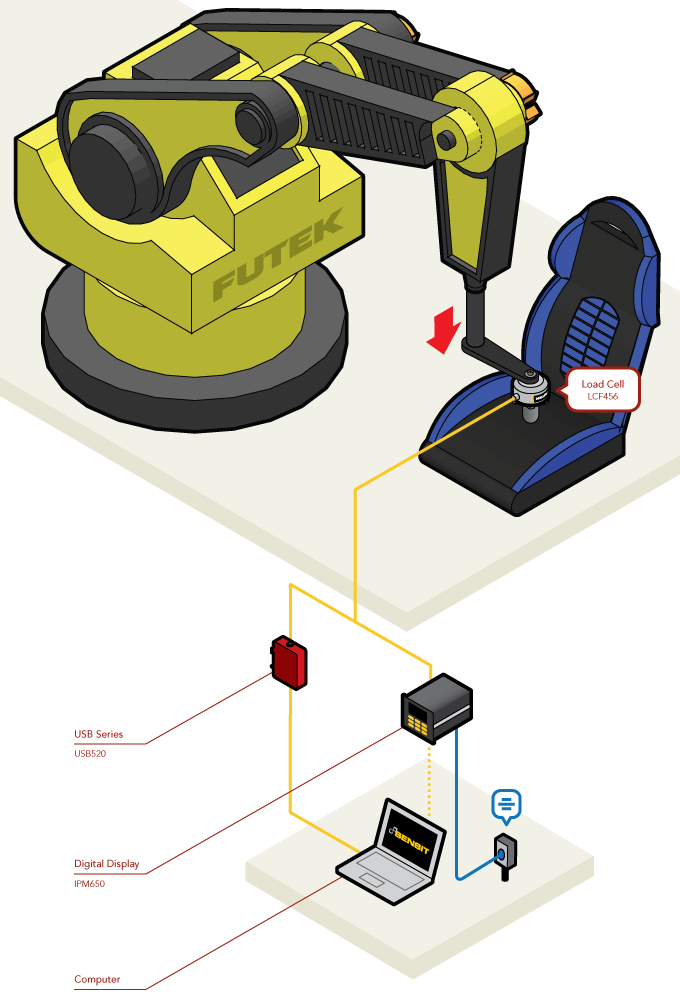

Automotive Seat Durability Testing

.

In the automotive industry, robots are used to test the wear and durability of seats. Automakers are studying how people of all shapes and sizes affect the upholstery, cushions and structures of seats over the life of the vehicle. FUTEK's LCF456 "wafer" type load cell is integrated with the custom test robot to quantify the compression force data exerted on a seat.

.

How it Works :

-

Car seats undergo robotic test that repetitively reproduce human movements and loads onto the seat under test.

-

FUTEK’s Fatigue Rated Pancake Load Cell LCF456 is fixed to the distal point of the robots arm to quantify the force that is applied in the process with high accuracy and repeatability.

-

The load measurements produced help engineers determine the quality of an automotive seat.

-

These force measures can be streamed to a computer for analysis utilizing FUTEK’s USB Solutions.

.