Material Force Testing

.

Materials testing helps companies and research institutions to obtain valuable knowledge for the development of new products, and the improvement of existing products. Non-destructive and destructive materials testing investigates the mechanical loading of a material up to break or up to a specific specimen deformation.

Material strength testing, using the tensile or tension test method, involves applying an ever-increasing load to a test sample up to the point of failure. The process creates a stress/strain curve showing how the material reacts throughout the tensile test. The data generated during tensile testing is used to determine mechanical properties of materials.

A common material tester is the hydraulic press, which applies different loads onto the test specimen. A precision load cell is connected to the material tester for force and load measurement.

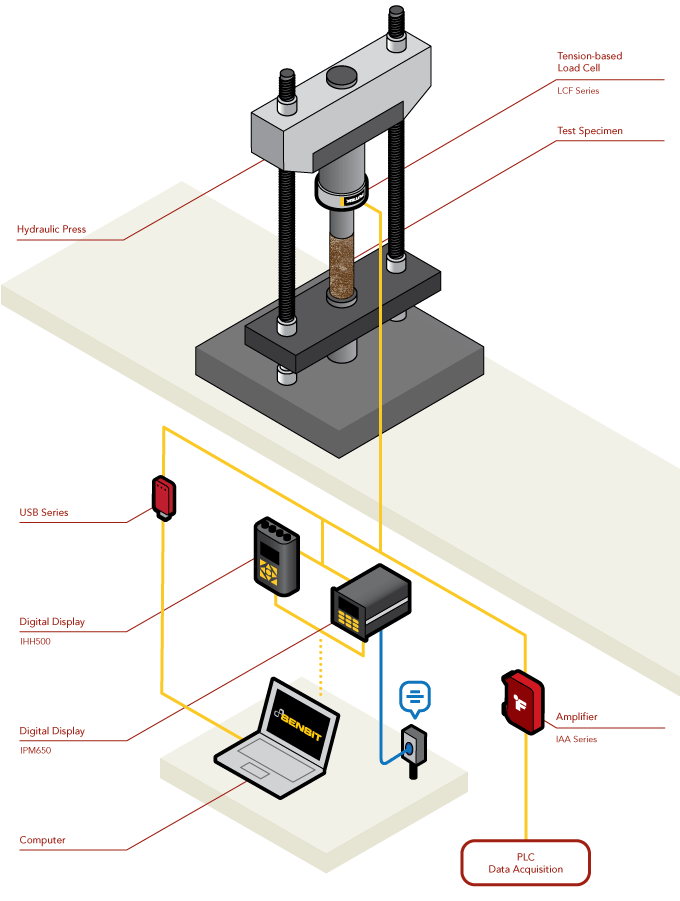

Utilizing a robust, high capacity pancake load cell (LCF Series), industrial operators can measure the force applied to test materials via a hydraulic press (material force testing).

.

How it Works :

-

Operators have installed a high capacity pancake load cell (LCF Series) into this hydraulic press material test stand.

-

Intended for tension-based measurements, the load cell will monitor the force applied to the test specimen - in this case a concrete pillar.

-

As the hydraulic press bears down on the concrete pillar, the LCF Load Cell's measure will be streamed to one of three instruments or amplified to a PLC via FUTEK's IAA Strain Gauge Analog Amplifier.

-

The LCF Series Load Cell's data can streamed to either of FUTEK's digital displays: the IHH500 Intelligent Digital Hand Held Display or the IPM650 panel mount display, or it can be streamed directly to the operator's PC via FUTEK's USB Solutions.

-

Any of these instruments can be paired with FUTEK's SENSIT™ Test and Measurement Software, which can perform data logging, live graphing, and monitoring up to 16 channels.