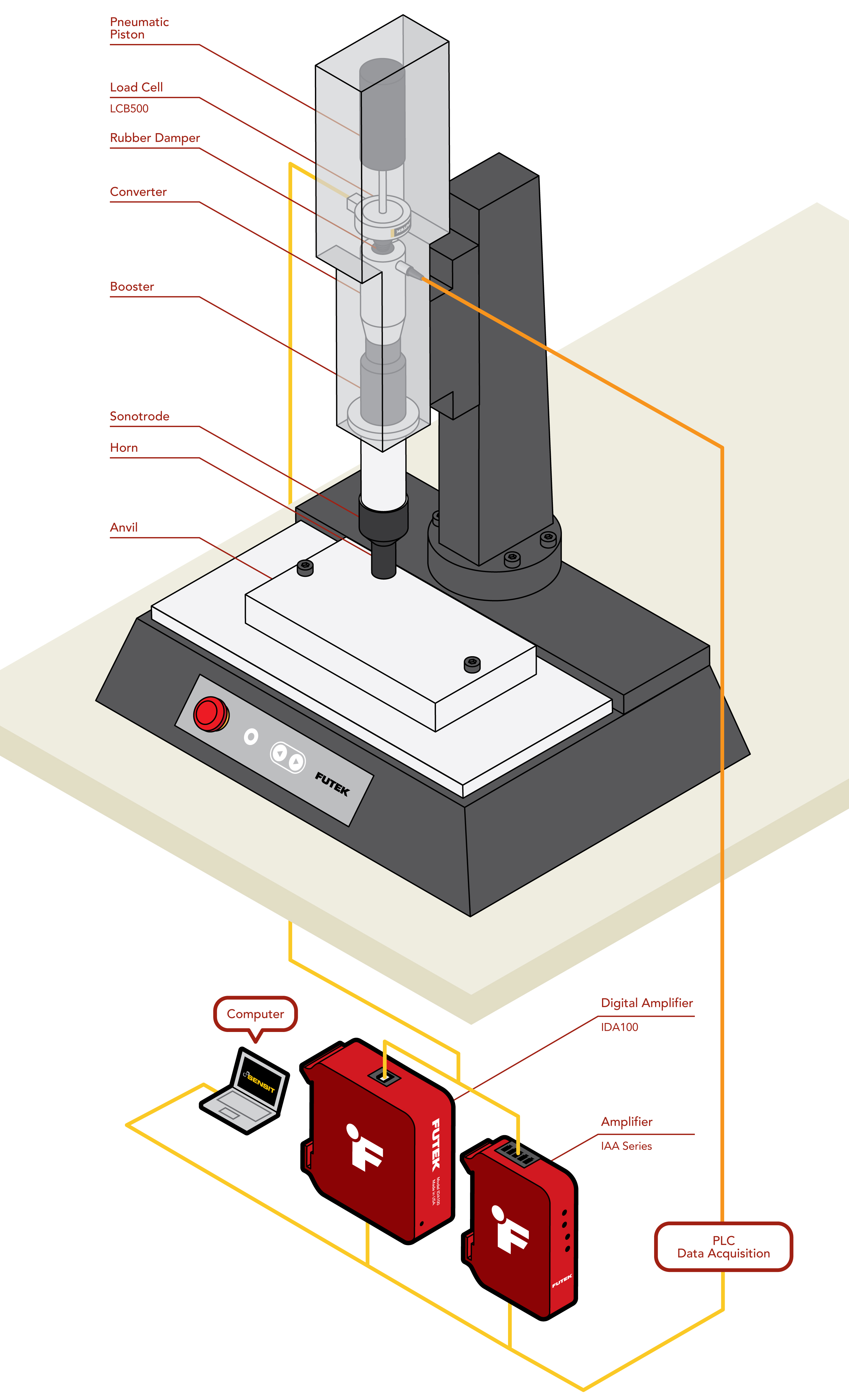

Ultrasonic Welding Clamp Force

.

Ultrasonic welding allows two pieces of material (e.g. plastic) to be welded together using high frequency vibrations. The result is a clean welding process, producing uniform and tight welds. This clean welding process is ideal for medical equipment, toys, semiconductors and consumer electronics. One of the keys to a clean weld is the proper application of clamping force. Too little force results in an incomplete weld, too much force results in deformed products. Incorporating an in-line load cell with the welding system allows the ultrasonic welder to deliver the correct amount of contact force to each part.

.

How it works :

- An LCB/LCF series load cell is mounted between the converter and the actuator that move the assembly.

- A damper is placed between the converter and the LCB/LCF series load cell to minimize the effects of high speed vibration from the load cell.

- Once the parts are clamped during assembly, the force transducer measures the force of the weld and how well the force is maintained.

- The IAA and IDA100 amplify and transmit the force signal to the PLC for clamping force control.

- In addition, the IDA100 allows the force transducer output to be recorded and monitored with SENSIT™ software.

- The data generated with SENSIT™ can then be used of traceability operations.

.