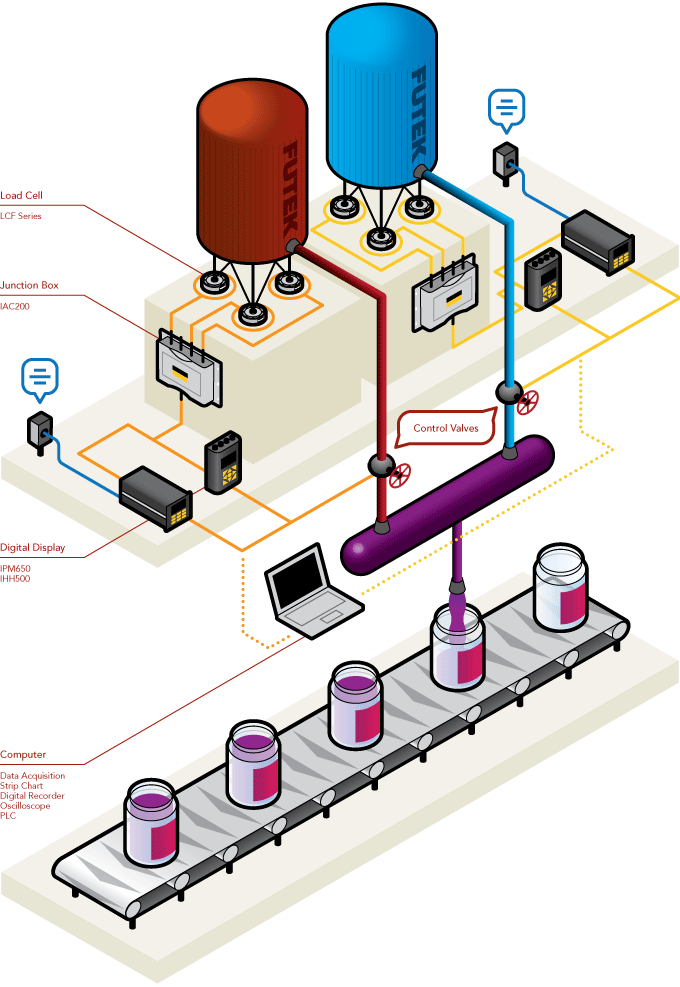

Dual Tank Level Controller

.

The implementation of load cells and instrumentation can automate many systems in tank dispensing applications. This process provides operators with accurate measurements of liquid ratios and triggers for valve opening and closing.

.

How does it work ?

- In this particular application, specific ratios of each liquid must be dispensed into the mixing vessel before being released into each jar.

- The selection of load cells can vary from "wafer" type to "force ring" type or load button, depending on the preferred mounting configuration and accuracy required. The choice of electronics to build this platform is equally important.

- To ensure accurate liquid ratios, several load cells were installed at the base of each liquid distribution silo.

- Each silo has been paired with either FUTEK's IHH500 intelligent digital display or IPM650 display. These instruments will monitor the measurements captured by the load.

- In such configurations, electronic options such as output options (analog or voltage), alarms/relays, and high resolution measurements can facilitate installation and improve system readings.

- Once a specific ratio of liquid has been released from each silo, the IHH500 or IPM650 triggers the control valve to close.

- The contents of the mixing vessel can then be released into the pot below.

.

.

Products used :

Multiple pancake load cells (LCF series) combined with instruments (USB solutions, IHH500 and IPM650).

.