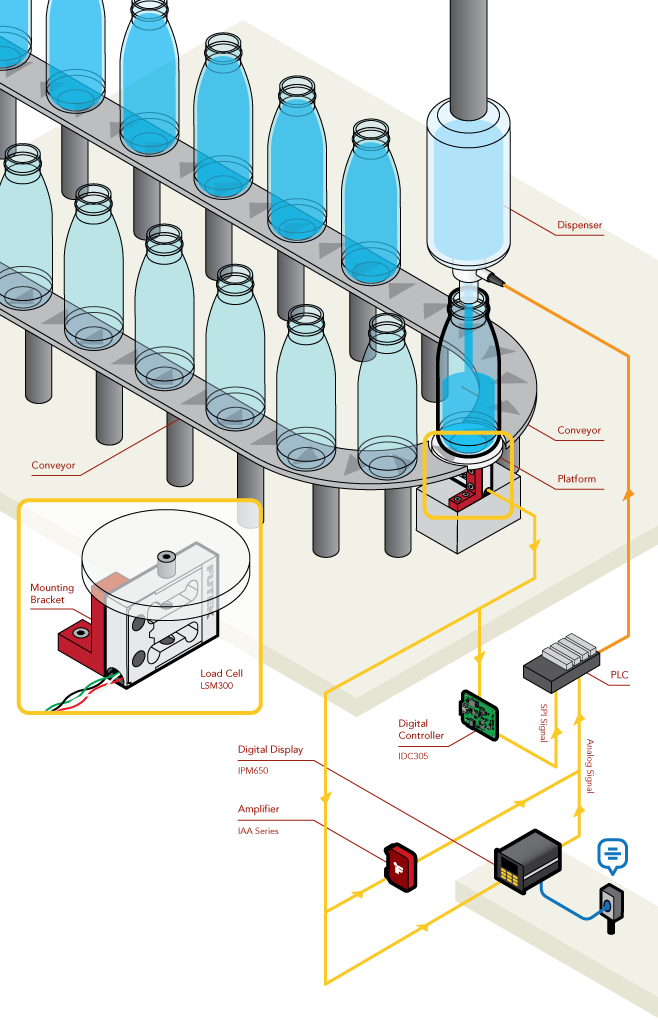

Bottle Dispensing and Weighing

.

One of the main challenges of automation engineering in the food, beverage, pharmaceutical or chemical industry is to ensure that bag packaging and bottle filling are within the specified weight, both to minimize waste and to meet regulatory requirements.

Beverage manufacturers know that overfilling bottles can result in huge production losses. Reducing overfilling by just one gram or milliliter per bottle can save thousands of dollars per year per production line. That's why engineers and production managers need accurate sensor solutions that can accurately measure weight and load and control closed-loop filling systems on automatic filling machines.

While there are several methods and sensors for controlling fill levels, physical weight is the most important process variable, even before mass, density, level or volume. By weighing the bottle, the control system is "counting the molecules," since each atom has its own weight. In addition, the weight measurement is not affected by differences in liquid density, temperature, viscosity or material aeration. None of these variables affect the weight of the final product.

The other solution is the conventional volumetric automatic bottle filler (also called an automatic liquid filler), which controls the flow valve based on volume. The disadvantage of the volumetric method is that material conditions can affect the final weight. Therefore, switching from a volumetric filler to a weight filler is economically attractive, as the weight filler offers the control system greater filling accuracy, regardless of the type of material or its physical/chemical conditions.

The high-precision load cells used in bottle filling systems are our recommended approach for the accuracy of automatic bottle dispensers.

.

How it works :

- An LSM Series load cell is mounted in-line under a platform supporting a container being filled.

- When the bottle is filled, the LSM Series load cell weighs the fluid.

- The signal representing the weight is sent to an IDC305 digital controller (SPI signal), an IPM650 digital display, or an IAA series analog amplifier (amplified analog signal) to convert the signal and send it to a PLC.

- The PLC or microcontroller, stops the dispenser when the correct fluid weight is reached.

- In addition to low non-linearity and non-repeatability, the LSM series load cell has minimal creep and built-in overload protection.

- Creep is the drift in the output of a force cell when a fixed load is applied. This means that the LSM series load cell is minimally affected by the weight of the platform and container, optimizing measurement accuracy.

- We also offer OEM solutions for the LSM series force transducers, which offer I2C, RS232 and UART signal outputs.

.