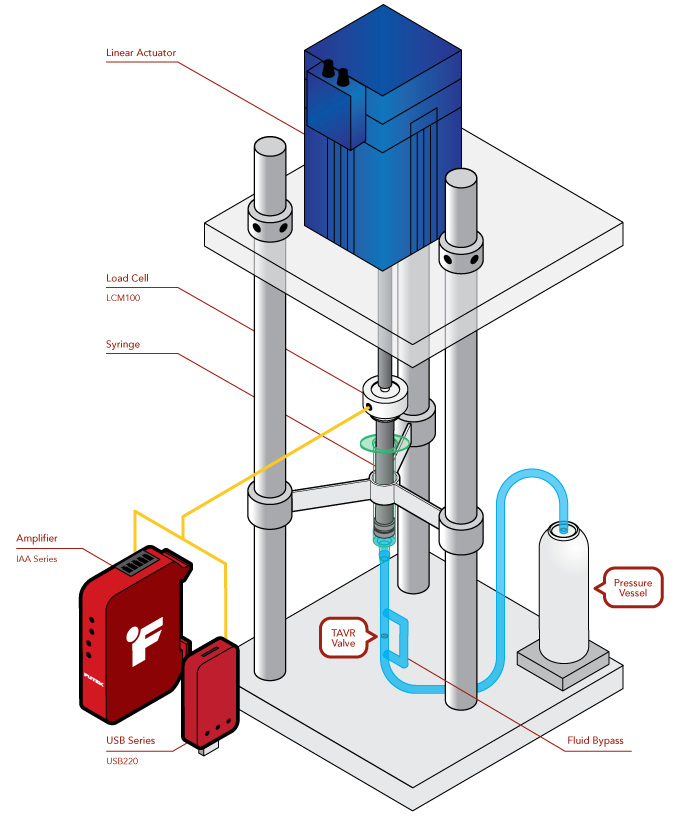

TAVR Valve Durability Testing

.

When one of your heart valves fails, you expect the prosthesis to be able to withstand the rigors of the human body. TAVR and TVMR valves must have the durability and reliability to stay in a patient indefinitely. Durability, in this case, is survival at extremely high blood pressures, because the last thing the patient or doctor wants is for the valve to fail in a cardiac event. To accomplish this, a load cell is placed between a linear actuator and a syringe plunger that is pumped down, forcing fluid into a small pressure vessel, allowing the system to remain at a constant pressure.

.

How it works :

- LCM or LSB series load cells are threaded in-line with a linear actuator and syringe plunger, measuring the force the linear actuator applies to the syringe plunger for test validation.

- When the linear actuator presses on the load cell/piston assembly, the fluid flow pushes the TAVR valve open.

- A check valve keeps the fluid moving only through the TAVR valve and a pressure vessel is used as a reservoir to allow the system to reach burst test pressures.

- The linear actuator then retracts, pulling the piston upward, forcing the TAVR to close and fill through the now open control valve.

- The USB220 displays and records data to a PC via FUTEK's SENSIT™ software. This data can be used to validate the accuracy and precision of the pressure generated by the syringe piston.

.

.

Products Used :

LCM series inline beam or LSB series S-beam combined with a USB220 data logging system.

.