Non-Magnetic Sensors Solutions

.

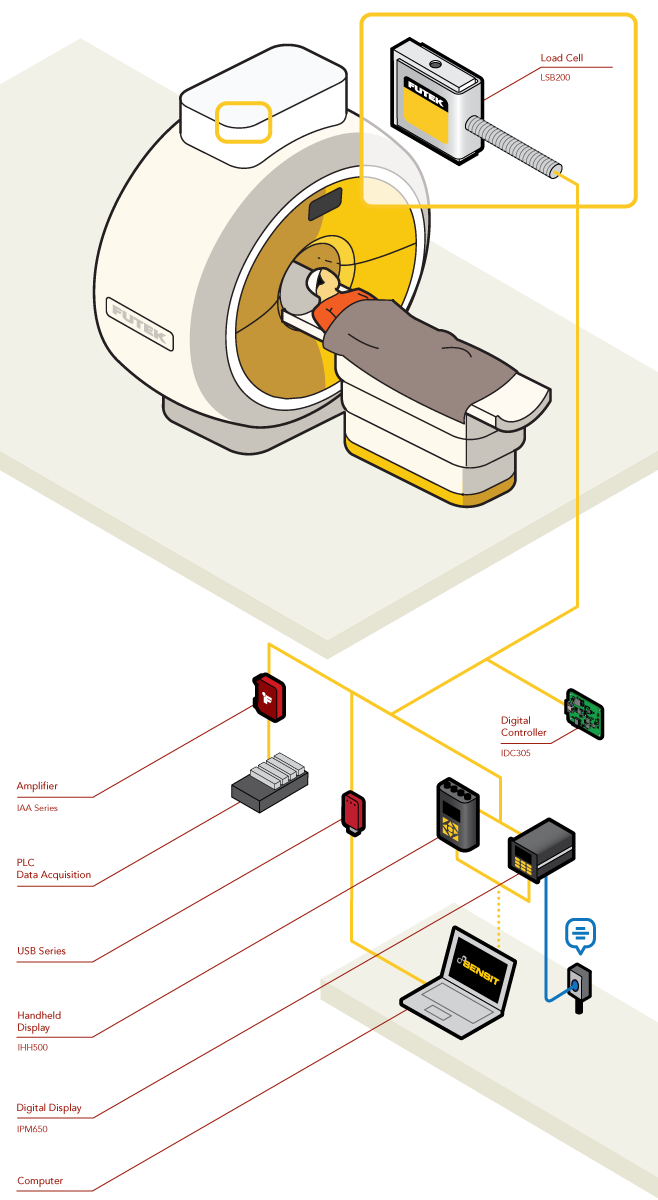

Sensors that operate in strong magnetic fields must not only have their measurements protected from alteration by magnetic fields, but they must not become a nuisance to that environment either. For testing and monitoring of load and force, a sensor made from non-magnetic, non-ferrous materials is required for this type of application.

.

How it works :

- Measurements in a high intensity magnetic environment require the use of non-magnetic, magnetically shielded materials such as beryllium copper.

- These materials serve two purposes: to prevent degradation of the sensor's measurements (due to magnetic fields) and to prevent the sensor itself from being drawn into the source of the magnetic field, thereby damaging the entire equipment.

- In addition, the use of magnetically shielded materials prevents any field generated by the sensor from distorting the measurements made by other sensors and instruments in the vicinity

- In this application, a miniature non-magnetic LSB200 force transducer is installed in an MRI to perform force measurements.

- The wiring and signal from the LSB200 are routed outside the MRI to the instrumentation, at a safe distance from the machine to avoid damage to the MRI and instruments.

- The signal is then amplified via an IAA series analog amplifier to a DAQ, displayed by a panel mount IPM650 display or IHH500 portable display, or recorded using the USB output module (USB220) using SENSIT software.

.