Vacuum Compatible Sensors

.

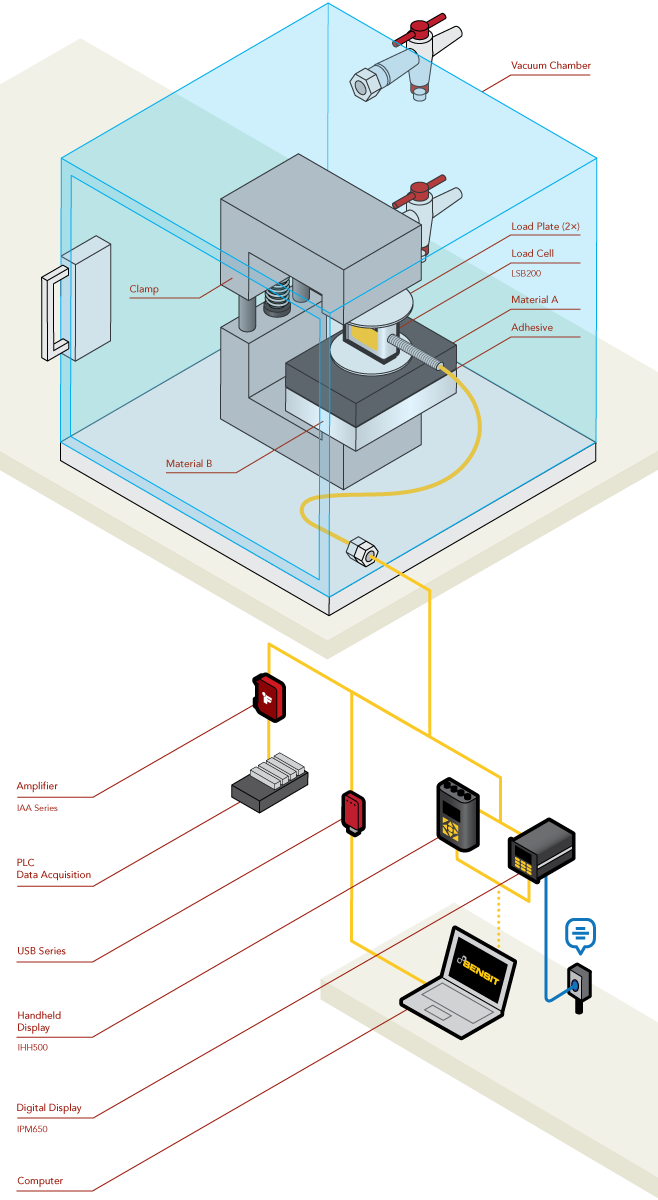

Testing and production of products in a vacuum or space simulation environment requires equipment that can operate without contaminating the chamber and interfering with the results. This requires low outgassing solutions that generate vapor emissions within strictly controlled parameters. For load and force testing and control, a vacuum compatible/low outgassing sensor is required for use in the vacuum environment.

.

How it works :

- In a vacuum environment, outgassing of materials occurs, as the pressure drops below normal atmospheric pressures.

- In an ideal case, these gases are removed by the chamber and this maintains the vacuum environment. However, the gases will most often deposit on the walls and any materials inside the vacuum chamber.

- This causes staining and/or corrosion on the material in the chamber. These stains can obstruct camera lenses and other measuring elements, affect sensor readings and damage components, often preventing any measurements from being taken in the chamber.

- Therefore, it is essential that all components in the chamber minimize gas emissions to protect the integrity of the environment.

- For FUTEK low outgassing sensors, specific materials such as wire, Teflon cable are used to minimize outgassing.

- In this application, a miniature vacuum compatible low outgassing force transducer type LSB200 is used to measure the force applied when bonding two materials in a vacuum environment.

- The LSB200 is placed in line with a clamp holding the two materials together, measuring the applied force.

- The LSB200 sensor cable is routed to the outside wall of the chamber in a bulkhead to maintain the vacuum environment and allow the signal to safely leave the chamber.

- The signal is then amplified via an IAA series analog amplifier to be sent to a DAQ, displayed on an IPM650 panel mount display, IHH500 handheld display or recorded with the USB220 output module to a PC with SENSIT software.

.