Fluid Flow Rate Measurement

.

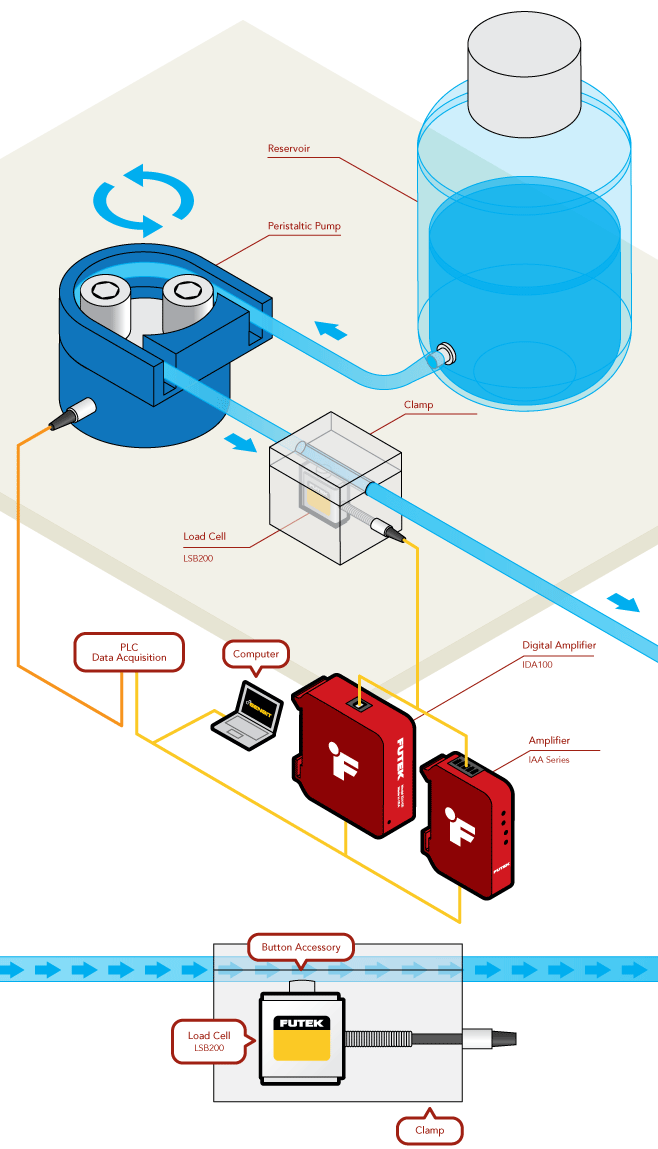

Measuring fluid flow in food production, blood infusions, catheterizations and chemical preparations requires sanitary and sterile processes. Non-contact measurement solutions, such as the use of an occlusion or obstruction in the tubing, is one type of flow measurement solution. In addition, this technique can detect bubbles and obstructions.

To measure the force exerted by the fluid on the occlusion, a load cell is incorporated into the obstruction mechanism. The obstruction mechanism assembled with the load cell sensor can function indirectly as a non-contact flow sensor.

The sensors have no contact with the fluid and are suitable for all applications with strict hygiene requirements, e.g. biotechnology, pharmaceutical or chemical industry.

.

Semiconductor industry :

Non-contact flow sensors are designed to detect the flow of liquids in rigid tubes of different diameters within milliseconds. This is a very common application in the semiconductor industry :

- wafer cleaning equipment

- lithography equipment

- mixing equipment

- chemical supply systems

- slurry lines

.

How it works:

- An LSB200 series load cell is mounted to measure the force emitted by the clamp to clamp the pipe.

- By creating this artificial flow occlusion, the fluid will exert an increased force on the pipe.

- The LSB200 measures the reaction force of the fluid, allowing the fluid flow to be measured.

- The IAA and IDA100 amplify and transmit the force sensor signal to the PLC system for flow measurement.

- In addition, the IDA100 allows the sensor output to be recorded and monitored via a PC running SENSIT software.

.