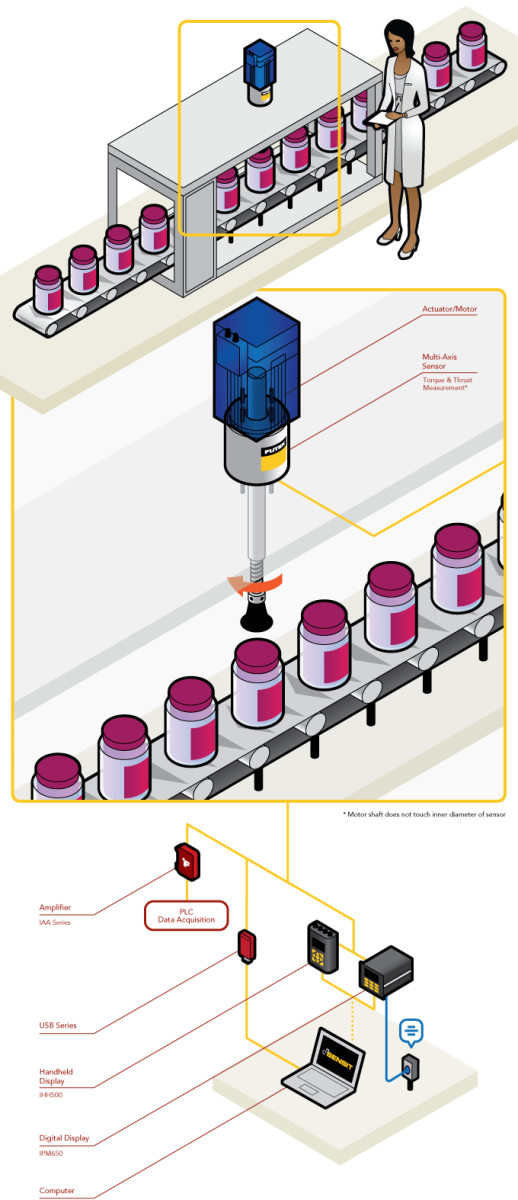

Automated Capping Press

How it Works

-

Operators have installed a biaxial sensor into their production line to monitor the actuator/motor powering the capping press.

-

Installed directly underneath the capping press' actuator, this biaxial sensor measures the torque and thrust exerted as each cap is sealed onto its respective container.

-

These torque and thrust measurements can be amplified through FUTEK's IAA Series Amplifier to a PLC, shown on a digital display (IPM650 or IHH500) or streamed directly to a PC using FUTEK's USB Solutions.

-

If the instrument is paired with FUTEK's SENSIT™ Test and Measurement Software operators can log, graph and capture all the data on the PC.