Robotic Spot Welding Force

.

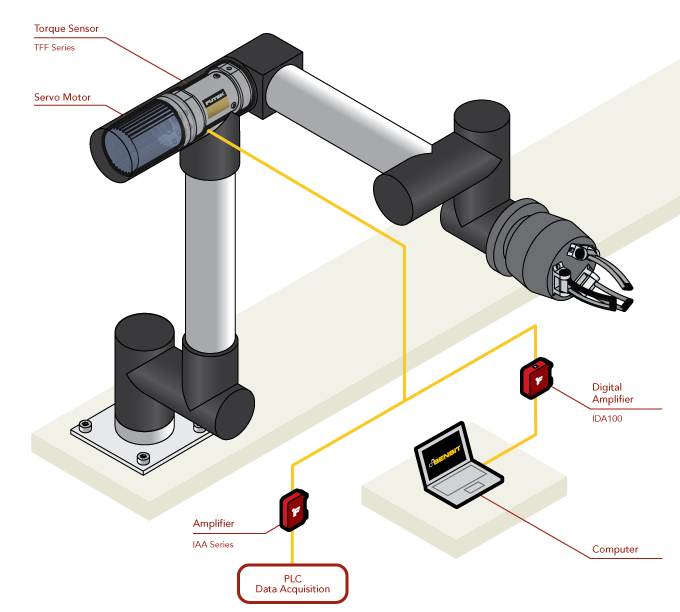

Spot welding robots can dramatically speed up the manufacturing process by automating the welding of complex or hard-to-reach assemblies. The robot must apply the same force to clamp the parts to be welded in order to achieve a strong and complete weld. To ensure this, an LCB400 Rod End load cell is used in-line with the clamp actuator to measure the clamping force during welding.

.

How it works :

- An LCB400 series load cell is installed in-line with the actuator controlling the spot welding clamps.

- When the actuator closes the gun, the LCB400 measures the force applied to the workpiece.

- The LCB400 measurement is then sent to the IAA or IDA100 series analog amplifiers.

- An amplified analog signal is then sent to the "PLC" controlling the spot welding guns, which allows the control of the clamping force.

- In addition, the SENSIT software can be used to record the sensor output for quality control purposes from the IDA100.

.